Descrizione

XCESX SERIES

EXPLOSION PROOF ENCLOSURES

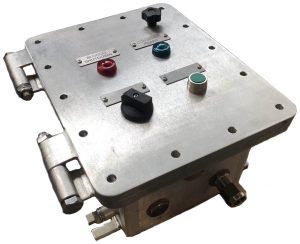

Designed for use in highly corrosive areas, the new cast stainless steel explosionproof enclosures provide the perfect construction material for offshore, petrochem, or volatile industrial areas where environmental conditions require additional corrosion protection.

The XCESX series of cast stainless steel explosionproof enclosures provide an alternative to traditional cast aluminum explosionproof enclosures which may become compromised or could break down over time in highly corrosive areas.

Rated for Class I, Division 1 / Zone 1 hazardous locations, the XCESX enclosure series carries UL, cUL, ATEX, and IECEx approvals for global applications.

Five standard sizes make up the initial offering from internal dimensions of 10”W x 14”H x 8”D up to 24”W x 36”H x 10”D.

Features include a watertight gasket and stainless steel cover bolts for Type 4X / IP66 ratings, stainless steel hinge kit, mounting panel, removable lifting eye bolts, cover alignment device, cast-on mounting lugs, and internal / external ground screws.

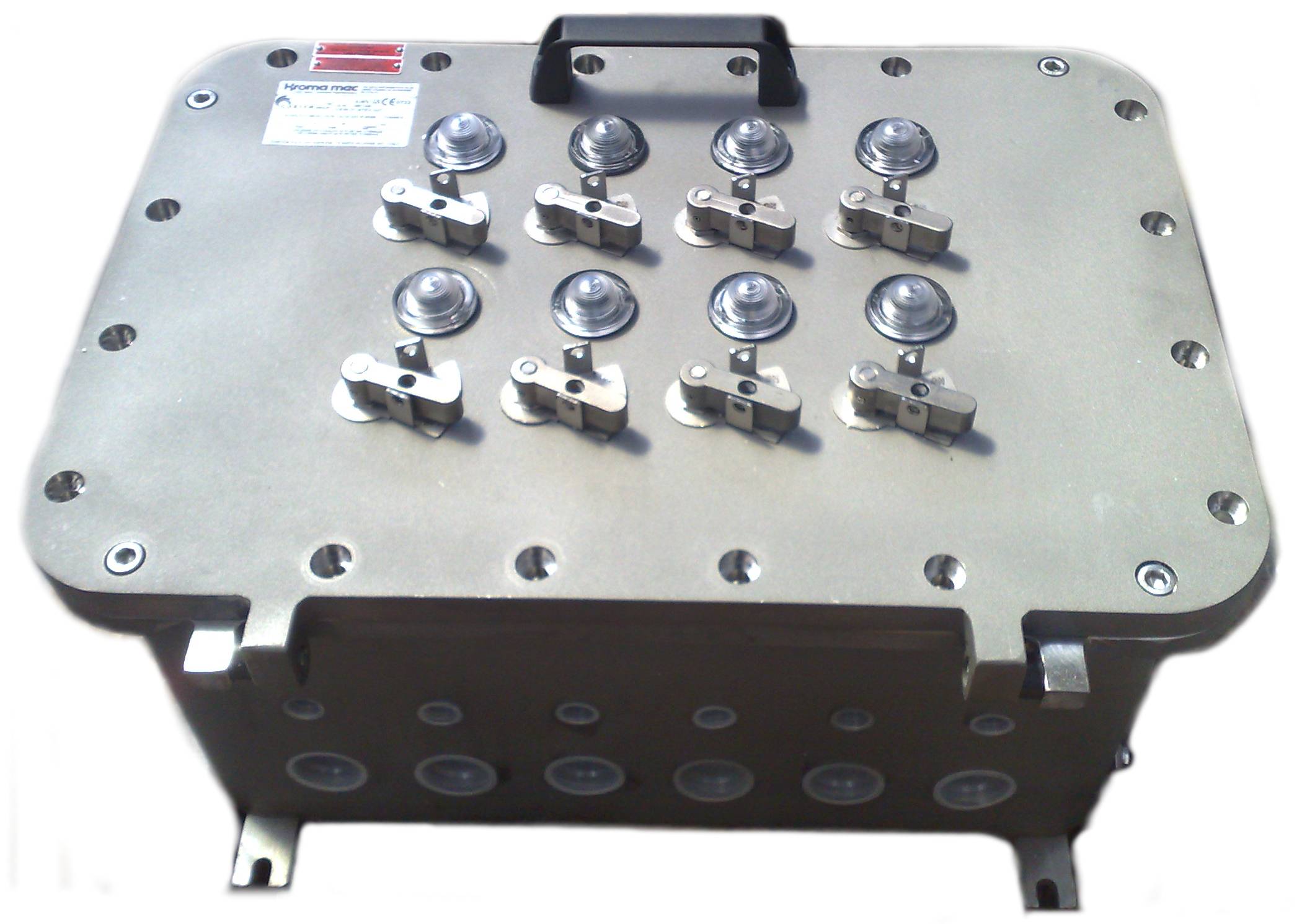

A flat plate cover allows for additional working area for viewing windows and operating devices such as pushbuttons, selector switches, and pilot lights.

Standard Features

• 5 standard sizes available

• Flat plate cover design

• Corrosion resistant, cast stainless steel 316L

• Stainless steel hinge kit

• Pre-drilled for mounting panel (mounting panel optional)

• Type 4 watertight gasket

• Stainless steel cover bolts

• Internal / external grounding screws

• Removable lifting ete bolts

• Lid-lifter cover alignment device

• Cast-on mounting lugs / feet

• Rated for Division 1 and Zone 1 hazardous areas

Design Options

• Stainless steel cover bolts for Type 4X additional corrosion protection

• Conduit (NPT & metric) and device (NPSM) drilling and tapping

• Auxiliary devices such as breather / drains and flame arrestors

• Custom machining – milling, counter-boring, spot-facing, blind drilled holes, entries, and chamfers

• Round or square windows

• Operating devices: pushbuttons, pilot lights, selector switches

Material

• Enclosure – stainless steel 316L

• Cover bolts – stainless steel 316L

• Hinge kit – stainless steel 316L

Class I, Division 1, Groups B, C & D

Class II, GroupsE, F & G

Class III

Class I, Zone 1, Aex d IIB

NEMA Type 4X

UL, cUL

IECEx UL10.0046U

IECEx Ex d IIB Gb

IECEx Ex tD A21 IP66

ATEX

II 2 G Ex d IIB

0II 2 D Ex tD A21 IP66